The Ultimate Guide to Setting Up Your Own Mini Dairy Plant

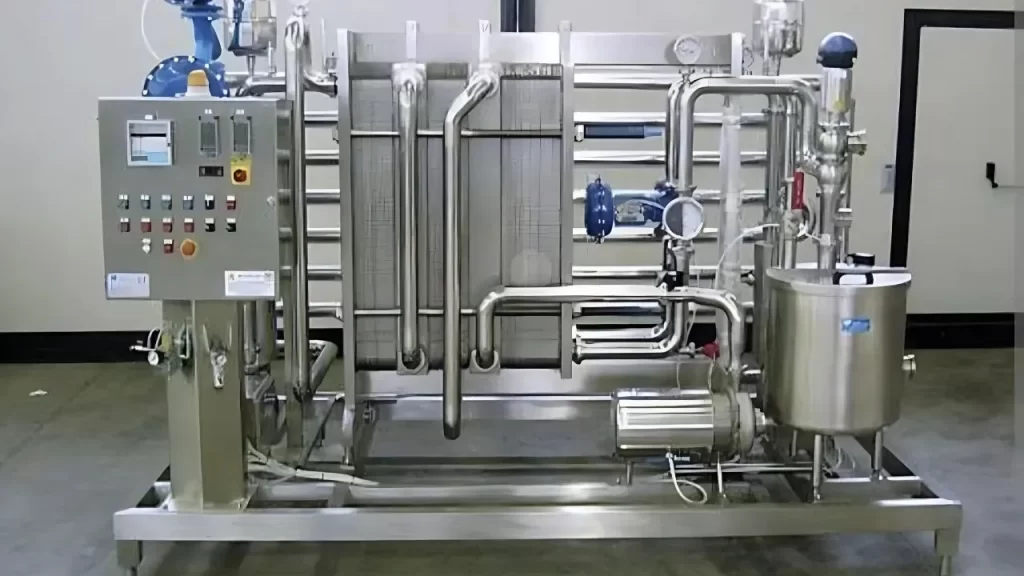

The dairy industry has always been one of the most profitable and essential sectors in the food industry. With the rising demand for fresh milk, cheese, butter, curd, and other dairy products, many entrepreneurs are considering starting their own mini dairy plant. Pranam Ji Engineering Works is a trusted partner that can offer mini dairy plant end-to-end solutions. We provide designing the layout of dairy plant to supply modern machinery, ensuring that your business starts on the right track. Benefits of Setting Up a Mini Dairy Plant High Market Demand: Milk and dairy products are staple items consumed daily in every household. Steady Returns: Since demand is constant, it ensures consistent revenue generation. Employment Generation: Provides opportunities for local workers and farmers. Support to Farmers: You can buy milk directly from farmers, ensuring fair pricing and better livelihoods. Scalable Business: A mini dairy plant can grow with time as you add more equipment and expand your operations. With the right milk processing plant layout, you can achieve efficient production and meet the growing market demand without compromising quality. Planning Your Mini Dairy Plant Market Analysis: Understand the local demand for milk and milk products like paneer, butter, ghee, and curd. Location Selection: Choose a site that is easily accessible for milk collection and distribution. Milk Processing Plant Layout: Pranam Ji offer a well-designed dairy milk processing plant layout to ensure smooth workflow, from milk reception to packaging. Budget Planning: Calculate investment costs for land, machinery, workforce, and utilities like water and electricity. Also Read: What Is Homogenized Milk And What Does It Mean? Choosing Dairy Equipments and Machinery A mini Dairy Plant largely depends on the high quality of machinery you choose. Modern equipment ensures faster processing, better product quality, and less wastage. Some essential equipment you will need include: Milk Pasteurizer: For heating milk to eliminate harmful microorganisms. Cream Separator: To separate cream from milk and produce skimmed milk. Homogenizer: For breaking down fat molecules and improving milk texture. Milk Storage Tanks: For holding milk under controlled temperature. Packaging Machines: For hygienic packing of milk and milk products. Pranam Ji specializes in supplying high-quality equipment and can offer you with the perfect machinery to match your production capacity and budget. We create the layout of dairy plant that allows smooth material flow, minimizes contamination risks, and increases productivity. Designing the Dairy Milk Layout A good dairy milk layout ensures that milk moves systematically through each stage — collection, chilling, pasteurization, homogenization, storage, and finally, packaging. The layout of dairy plant must separate clean areas from dirty areas to maintain hygiene. Considerations when designing your dairy milk processing plant layout include: Raw Milk Reception Area: Should have space for unloading and testing milk. Processing Section: Must house pasteurizers, separators, and homogenizers with proper space for maintenance. Packaging Area: Should be clean and isolated from raw milk handling zones. Cold Storage: For storing finished products before distribution. Utility Area: For boilers, refrigeration units, and other supporting equipment. Pranam Ji, you are a trusted industry expert and we offer complete support from conceptualizing the layout of milk processing plant to supplying durable equipment and even helping with after-sales service. A well-designed layout of dairy plant not only ensures productivity but also helps in producing safe, high-quality dairy products that customers will trust. With growing demand for fresh and hygienic milk, now is the perfect time to invest in a mini dairy plant and take advantage of this profitable business opportunity.

The Ultimate Guide to Setting Up Your Own Mini Dairy Plant Read More »