The dairy industry has always been one of the most important in India, moving the lives of millions of farmers and consumers. Among the most popular options is the Mini Dairy Plant, which is both cost-effective and practical for small to medium-scale operations. At Pranam ji Engineering Works, we supply fresh milk to produce value-added products like curd, ghee, butter, paneer, and flavored milk, the demand for dairy products is constantly growing. The mini dairy plant setup cost depends on plant capacity, and type of products you want to produce, such as milk, paneer, butter, or ghee. We offer customized solutions and efficient equipment, smooth installation, and long-term support.

What is a Mini Dairy Plant?

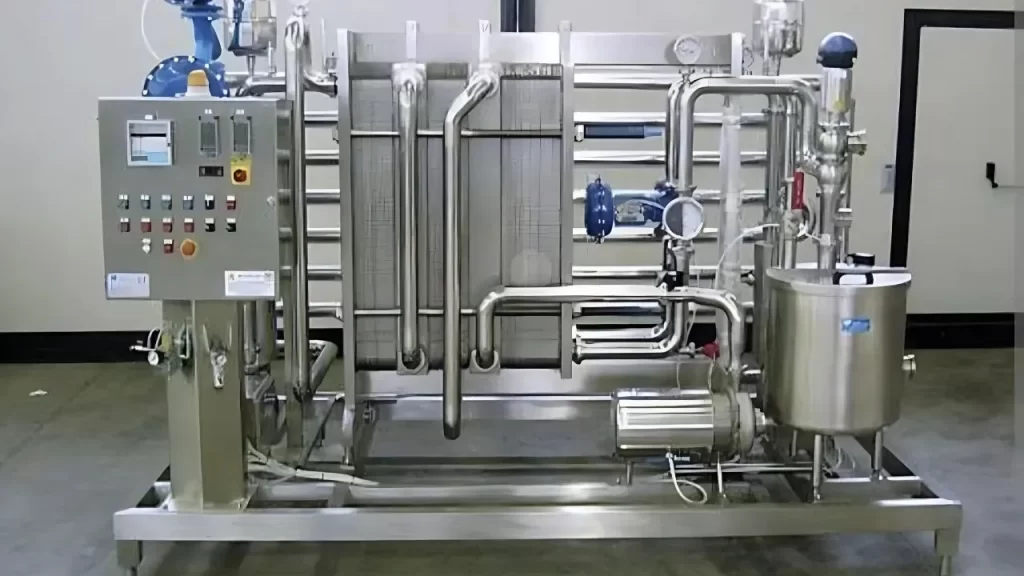

A mini dairy plant is a shortened version of a large-scale dairy processing plant which is designed for small and medium-sized businesses or farms. It allows dairy entrepreneurs to process milk into products such as pasteurized milk, butter, ghee, paneer, yogurt, and flavored milk. Unlike traditional methods that require heavy manual work, a mini dairy plant automates the process, ensuring higher hygiene standards, faster production, and consistent product quality.

Also Read: Complete Guide to Dairy Milk Chiller Plants and How They Work ?

Benefits of a Mini Dairy Plant

Investing in a mini dairy plant comes with several benefits:

- Low Initial Investment: Compared to large plants, the setup cost is affordable, making it ideal for startups.

- Flexibility: You can start small and expand capacity as your business grows.

- Local Market Demand: Fresh milk products always have demand in nearby towns and cities.

- Value Addition: Processing milk into paneer, butter, or ghee gives higher profit margins.

- Employment Generation: Creates job opportunities in rural and semi-urban areas.

Understanding the Mini Dairy Plant Setup Cost

- Capacity of the Plant: Mini dairy plants come in different capacities, usually ranging from 500 liters per day (LPD) to 5,000 LPD.

- Type of Products: If you also want to produce value-added products like butter, ghee, or paneer, you will need more machinery, which increases costs.

- Quality of Equipment: Using stainless steel equipment designed for food-grade quality adds to the durability but also influences the price.

- Automation Level: A semi-automatic plant costs less compared to a fully automatic one.

- Other Costs: Infrastructure like buildings, water supply, power connections, and waste management systems also add to the overall budget.

When it comes to setting up a Mini Dairy Plant, choosing the right partner can make all the difference. This is where Pranam Ji comes in. Known for its reliability and expertise, We not only manufacture equipment but also offer complete project guidance, installation, and after-sales support. We offer design, fabrication, installation, and after-sales service. We offer complete solutions, from design to installation, ensuring you get a ready-to-use system that meets industry standards.